First Remove the seat from the rail.

Remove the inner rail cover.

Remove the 10mm acorn nut from in front of the seat center rail.

Slide the Seat all the way to the back and remove it from the rail.

Now make sure that the fingers are able to move half of the broken ones

I have had to deal with are because the fingers won't pivot.

Shoot PB-Blaster on it and work it with a pair pf pliers until

It moves freely.

Now manually fold the seat in half.

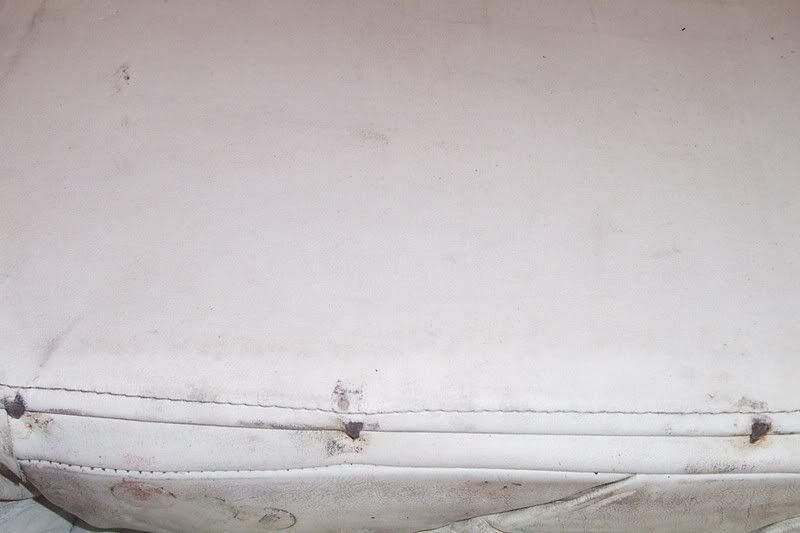

Pry up the fingers that are holding the material on.

Remove all the material off the fingers.

Cut the hog rings loose that are holding the side bolsters on.

Pull the seat back up to get to the release mechanism.

Look for the broken wire and remove it.

Go to the hardware store and get Stainless Steel cable 5 foot (1/16th) and 2 ferrules.

For the Longer run you need 3 foot, for the shorter side you need 2 foot.

Loop the cable through the open hole.

Now slide the ferrule on the longer side of the cable and insert the short side

that is through the release mechanism.

Pull it so that you have made a eyelet, and that the shorter end is almost at the ferrule.

Pull the Long end and Crimp the ferrule closed.

Run it over to the release holder slot.

Use a small piece of vinyl tube to act as a rub guard.

Insert the cable through the seat pivot hole, and slide the ferrule onto the cable.

Insert the cable in to the hole of the finger release, and feed it back into the ferrule.

Pull Tight on it so that the release finger on the right matches the one on the left

(a tad tighter won't be that bad as it will stretch.).

Crimp the ferrule closed Cut off the extra length of cable that you have on the outside of the ferrule.

Replace the Seat material.

Where you cut the hog rings, you can use a hole punch and punch a hole in the material.

Then instead of using hog ties, use wire-ties.

Stretch all the material back over the fingers, and tap closed with a hammer.

Reinstall the seat and enjoy.