Installing Your Convertible Top

Things that can make it easier.

The 10mm ratcheting box,,, it is the bomb and no longer available at a AutoZone near you.

The new TMI POS rear cable is using 11mm Nuts, so you will need a 11mm wrench too. They are available at

SEARs, NAPA, Nothern Tool, but watch for sticker shock, Napa was 2 times higher than

Northern tool.

Hammer

Center Punch

10mm offset ratcheting wrench Must Have

Heavy Duty Electric/Air (can use a hand) Stapler and 3/8 or ¼ galvanized staples

Good number 2 Phillips screwdriver

Wide blade Straight Slot screwdriver

Wide blade Jewelers Screwdriver Straight Slot

Razor Knife and new blades

3M Hi-Tack spray adhesive or 3M weather strip adheasive

Clear Silicone Sealer number II

Roll of 1 inch wide by ¼ inch thick closed cell foam

Small Brass Flat Link Chain 1 foot

CARB Cleaner 1 can

Rags and Paper towels

Old News Papers

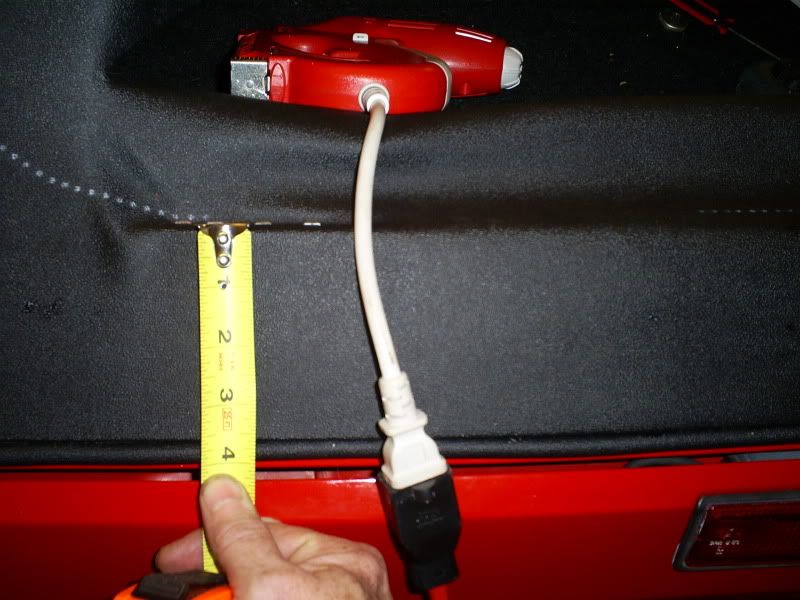

Measuring tape

Plastic bag to hold parts for a bit.

Flat steel anvil bout 1 X 2 X3 inches or a Large flat Punch

Drill and a assortment of Bits

2 or 3 Plastic Spring clamps

4 feet of broom stick and 2 large vise grips

Needle nose pliers

Flat nosed pliers

Diagonal cutter

Masons Twine

Long Hemostat’s

WD-40

Vasoline, Ky, or White grease.

Ice Scraper

If your top's struts have seized, they can be replaced with new ones.

OEM Lift-O-Mat part number: 155 671 997 A

Sachs-Stabilus-Boge replacement part number: SG401018

As of September 2007, the following places carry the aftermarket replacement strut: Rock Auto, Auto Parts Warehouse and through special order at your local Pep Boys.

Creating your side Cables

Depending on if you bought side cables or decided like me to make your own.

8 foot 1/16 stainless or galvanized Steel cable

8 foot 1/16 ID vinyl hose

6 1/16 cable swedges

6 inches of flat brass plumbers chain

Cut the steel cable in half

Cut the vinyl tube in half

Cut the vinyl tube 35 inches long

Insert the cable in to the vinyl tube

On one end of the cable insert the swedge

Loop the cable and force it into the swedge.

Do not leave any bitter edge of the cable exposed out of the ferrule.

Now pull the long side to make a small loop

Tighten the swedge ( I used my ratcheting Amp Tool )

Pull the vinyl tube back to the swedge.

Now the cable length with the 2 lengths of brass flat chain must be 37 ¼ inches long from the end of one loop to the other. Otherwise the total length of the cables is 37 ¼ inches long period.

Take the Brass Chain and cut off 2 links, then on the flat link insert a centering punch and using wood Hammer that punch into the chain to expand the hole. It has to fit over the steel stud on the front frame.

Slide the swedge onto the cable

Insert the flat brass chain onto the cable on the other non-expanded side,

Insert the bitter end of the cable into the swedge.

Measure the length of the cable assembly to be no greater than 37 ¼ inches long. For 81 tops you need an additional 3/4 of an inch

Tighten the swedge. BE SURE YOU GET YOUR SWEDGE TIGHT....

Now repeat for the other side and place in your plastic bag for use later.

It is gonna look like this

Creating your own rear cable.

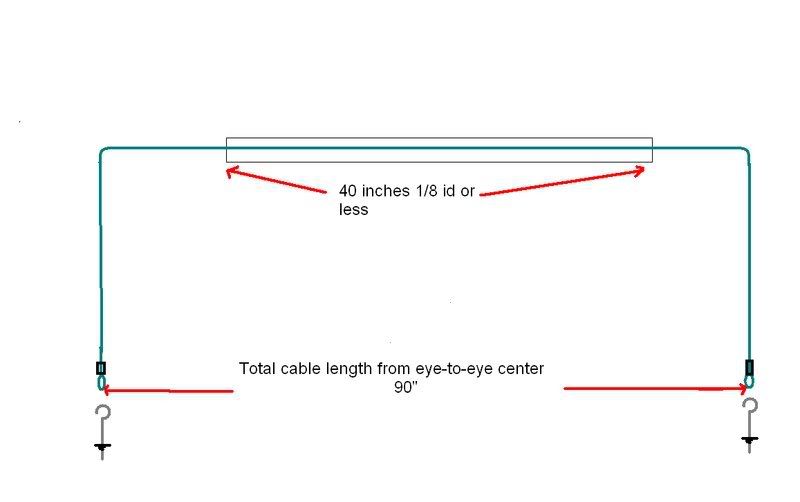

found a pristine genuine VW top cable.... I have the pic's and the measurements for you...

That is a steel outer sheath crimped to the end of the cable.

The sheath has a width of 1/8th of and inch and is about the same size as the cable itself.

The total length of the rear cable is 94 inches long from end of bolt to end of bolt.

The rear sheath is 40 inches long.

The cable is 27 inches on either side of the rear cable to the end of the bolt

The bolt is 2 inches long and the threaded part is 1 1/8th of a inch total.

The bolt is 3/16 inches wide.

Now with all that information we can manufacture our own rear cables that are structurally as sturdy and the same dimensions as the genuine VW cable at a 1/8th of the cost.

So for all you folks that don't want to bother and want to pay the 40 to 150 for a new rear cable, and IMHO the TMI cable is a crappy one. Just make your own and send me the difference....

So the operative word is that the cable is only 90 inches long. the bolts are 2 the sheath is 40.... Go forth this spring and replace...........

For outer sheath you can use brake line and run your cable through the middle.

When installing it, make one eye up remember that if you are using Eye-Bolts, to place the cable through the eye first.

Using Vasoline or KY (KY for canvas is better as it is water soluble to remove, grease the inside of the cable tray, and about ½ inch up from the bead of the outer vinyl covering.

Then run the unmade end from the inside through the split,(out of the feed hole) Place one of the boot tabs on for the left or right side around the cable tray now place the remaining boot tab on and the other corner, then back in the feed through and the split.

Take your eyebolts and place in the whole and lightly two spins only place the nut on. (both sides).

Take the free bitter end of the cable and insert it into the swedge.

Take the bitter end through the Eyebolt, and back through the other half of the swedge.

Pull all of the slack that you can out of the cable and start it in the cable tray.

Pull the remaining slack out, then Crimp the swedge, Crimp it good.

Now you can finish installing the cable in the cable then tighten the eye bolts to obtain proper tension and fitment.

Inspecting the door seals, and you can see that the Rain gutter trim isn't fully up where it is supposed to be.

Placing it to the proper position ensures that Water will not get a direct shot at the seals. I have gone so far as to place a small piece

of Silicone to plug the little hole between the Plastic and the rain gutter.

Labeling things isn't a bad idea.

De-Construction

Open and close your top look at the attachment points, do it a few times.

With the top closed

Remove the 2 corner plastic pieces and screws place in the Bag

Using a Razor Knife cut the top off from the rear quarter glass seal cut the vinyl only.

Cut the Top to the upper corner down around and above the bead all the way to the other side rear quarter glass seal, you are cutting the off the rear cable Pull it over the headliner at the corner so you don't cut nothing but the top.

Cut the vinyl 1 inch from the rear glass, you are cutting the top away from the window. CUT ONLY THE

TOP VINYL TOO DEEP AND YOU WILL SLICE THE REAR STRAPS THAT SUPPORT THE WINDOW.

Pull the top back to the front of the car, and cut the black vinyl ties on the sides and continue to pull it off the car towards the hood.

Cut or pull the top off from the front lip

Your top will now look like this but with padding on

Remove the rear side window glass upright seal by inserting a flat blade screw driver between the seal and the seal tray in the middle of the tray (carefully not to tear or puncture the rubber,

Then prying back on the blade the Seal will lift out of the tray, now slowly get the front to come out by Gently by pulling on the seal at the middle so that your fingers can touch together front to back, then pull upwards on the seal to release it from the stop at the bottom now that the bottom is out pull down to get the seal to come free of the top stop.

Get the middle of the seal loose, then grabbing the middle, push it down out of the Keepers

then up out of the bottoms keepers.

Remove the 4 Phillips screw holding the tray to the frame, and place the screws in the bag,

Insert your flat blade between the seal tray and the frame and pry it off the old dead foam.

Do it in easy steps the entire length or you will bend the tray.

You do not have to remove the B-Pillar Seal at all. So leave it alone.

Now remove the seal from the other side.

Open your Trunk lower the rear seat top and parcel shelf and look up to see where the fingers are holding your headliner.

If you can't see your headliner you will need to remove the Card boards by pressing he center out of the button

Bend the metal fingers to 90 degrees and pull the headliner off the keeper fingers there are 6 or 7 of them

Remove the headliner welting off the Top Frame cover (where the unlatching buttons are) this will remove the headliner from being attached you will need the room.

Open the top fully.

Remove all the screws that hold the top frame keepers and gently pry off should be about 10 of them

Remove the 2 Screws from the front “A” pillar seal lip

Carefully pry out the front seal in the middle, and then pull about ¼ inch to the front to release it out of the holding clip, then CAREFULLY work the front out, it is usually glued to the tray in the front, so I use a flat blade in the tray between the seal and tray.

Remove the 4 additional screws.

Pry the seal tray off the frame in the same manner as you did the rear

Using a Ice scraper clean off all the dead foam of the frames and seal trays.

On the leading part of the front frame, you will need to carefully pry from the back the first two nylon keepers to remove them. Take the dead vinyl off the front frame

Get as much off the tray as you can.

Using carb cleaner on a paper towel wipe down the frames to get all the goo off.

Clean is good

Pull off the vinyl off the rear trays, the front frame and the leading windshield frame,

Clean all the goo………..with carb cleaner.

Drill out the rivets in the front frame, and the rear frame

Make sure that you test fit your trays back to the frame and adjust as necessary as you want them to lay flat.

Now open the top fully and latch it.

Removing the Rear Window

Remove the Defroster connectors and the plastic covers on them

The connectors have two little clips, undo them then push them through the lip of the seal and unwind them

to the bottom, and remove them from the bottom seal.

From the outside of the car,

Lift up the outer edge of the Seal insert your flat blade between the window seal and the window frame at the rear, start at the corner.

While you are gently prying up and out on the seal in a rocking motion gently reach around the frame and un-do the seal from the inside lip.

Using a rocking motion with the screwdriver you will get the window out remember

unwind the defroster wires gingerly out of the gasket remove the plastic covers off the wire ends

The window will pop right out, you may have to work your flat blade down and around a bit.

Remove the gasket from the window glass and Clean the hell out of it, if there is plumbers putty you have to remove all traces.

Do not forget to clean the inside grove where the glass is, cleanliness is a must.

Scrape off the crud from the glass and then clean with carb cleaner to remove all traces of the crud

Return the gasket to the glass, the holes for the defroster wires are on the bottom and the sides. Work the gasket by holding 30 to 60 degrees off the glass the gasket will slide right back on.

Now set the assembled rear widow aside.

Using your flat Jewelers screwdriver pry up every one of those 120 to 200 staples, after they are up, remove them with your large flat pliers, after you remove 50 of them you can probably zip the remainder of the vinyl with the staples out.

Carefully inspect the frame for broken staple bits, and remove as needed.

Clean the tray of any and all rust, sand smooth Spray with a rust destroyer/primer, let dry and paint, remember to use a mask to prevent overspray on your headliner

.

Open the top halfway up, and use the broomstick and vice grips to lock it in that position.

Remove the struts by removing the clips and the washers, and place in the cable tray, you will need the room

Now is a good time to test your struts, with a Phillips Screwdriver inserted into one of the holes use it as a fulcrum and try to compress it against the floor, it should compress and then shoot back, if it doesn’t compress then it is bad, if it is really slow or bent then it is bad.

Now using your 10mm offset ratchet remove the nut off the rear cable You can get to it from the top use your finger to gauge how many threads are out, you will need to tighten it back to that spot.

Loosen the nut, and after about 5 or six clicks, to will spin freely off. Place the nut in the cable tray and with your hemostats or needle nose pliers remove the cable out of the tray on both sides the nut turns down to loosen and up to tighten Lefty Loosey, Righty Tighty.

With the ends of the cable out remove it from the cable tray with the beading.

Wow all that just to remove the top….. remember that installation is the reverse or removal.

You will need to remove the rear cable from the remainder of the top, I usually can rip it out…

Remove the Side cable bits from the front frame, and bend the finger up and remove the spring off the rear frame. Bending it at about 90 degrees is a good thing.

Clean your rear cable and spray the hell out of it with wd40.

Measure your rear window, make sure that the bottom edges are the same length from the cable tray, if they are within a eighth of an inch that is ok, if they are more than that then you will need to adjust it.

The Rear Window Frame has to be square, measure the frame from the diagonals. It has to be about 1/16 of and inch off or less… bend the corners as needed think rectangle versus a parallelogram,

If your window frame isn’t the same distance between the top edge of the lower part of the frame to the top of the cable tray, adjust the thing… it has to be equal distance.

Take the time now to oil all pivot points on your top, I start with WD-40 and then open and close the top a few times, then switch to regular motor oil, then continue to open and close it a few times.

Take your closed cell foam and place it on the bottom of the seal trays.

Look at your pig tail seals, that the rear upright frame mates with when the top is up, if it is cut or split along the body you need to glue it back in place, cover the edge with silicone sealer, as that is part of the water tight seal.

Since I last left you your top needs to be in the half up position and locked with the broom safety

Find the center of the cable tray and mark it with a sharpie on the lip of the body. I measure between the corners of the trunk

Find the Center of the rear cable sheath mark it with a sharpie.

Loosen the Safety and close the top frame.

If you are installing the padding, you will need to drill out the rivets that hold it at the front and rear of the frame, then carefully remove it off the front lip of the front frame

remove all the staples that holds it at the back, Working from the rear fold it over the windshield

You will find the front secured by a steel rod with a few finger holders, careful bend them up at 45 degrees, then pry the bar out of the side holders, cut the padding strap on the bottom…..

Now toss that sucker away

To install the padding fold it over the hood shiny cloth down so that the steel rod is pointing fingers up.

Place the steel rod in to the keepers and bend the two middle fingers through the cloth back over it.

Spin the rod 90 degrees and force end of the rod into the slots and the rest the rod back into the fingers.

Tighten all the remaining fingers by forcing the rod securely into the fingers and smacking with a hammer.

Place the vinyl padding support in the notch in the front bar and around the bar in the back

Now work the padding strap back through the rod, and over lap the cut ends and sew back together with a couple of wire ties pointy edges down, or remove the covers of the nuts on the side frame and remove the bar and rerun the strap, my cable tie is easier……

Now lay the pad over the top frame and square it to the rear and center it left to right.

Unlatch the top, and place newspapers or material on the seal and over the windshield, then close the top

Spray Hi-Tack to the front steel lip, and the back of the material and foam lip of the pad.

Allow to dry for 15 minutes.

when dry place the horse hair to the rear of the front bar and then glue the foam to the steel bar on the front, smoothly followed by the cloth get it smooth and make sure it lays flat..

Allow another 16 minutes to cure.

At the rear of the pad you will need to staple the pad to the frame

You can pop-rivet the strap or nylon wire-tie it in to the hole either works well, just make sure that the sharp end of the wire-tie in on the inside.

Then lock the top down.

Stretch the cloth to the back fold the bitter end under and staple in about ten places to the rear of the frame. Make sure that you seat the staples.

You can do the same for the front rivet too.

Your top pad is now installed and looks sharp..

Here comes the fun part……

Place your top on the car, take the pocket and place it over the front lip and drape it into position.

Find the two boot tabs and cut them loose and put in your pocket so you will know where they are.

Fine the center of the top measure between the seams and divide in half and measure over or if you have the notch for center then cool

Place a small mark right above the bead.

Measure the distance between the outside edges of your boot hooks mine was 22 inches,

Place one mark at 11 inches from center on both sides, this will insure that your boot fits tight at the hooks.

Cutting the cable relief

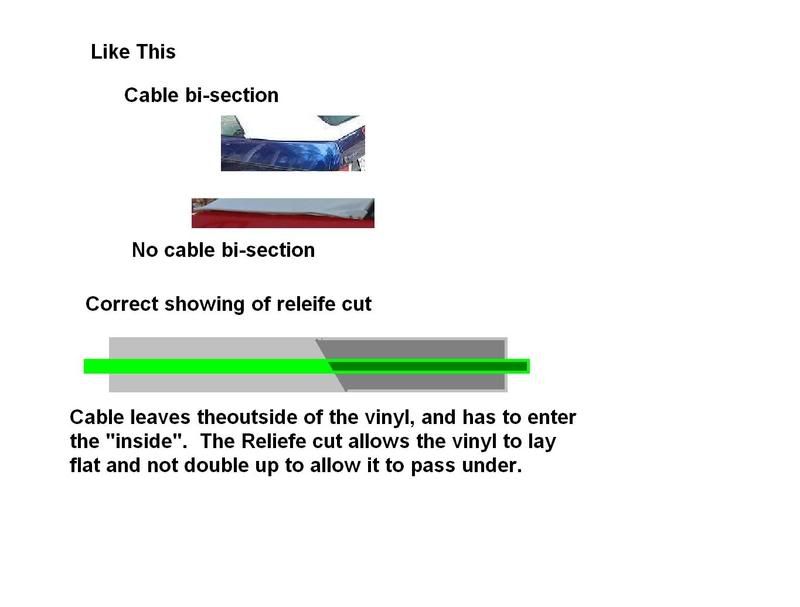

Now find where the cable exits the outside of the top and enters the inside, as you have to make a relief cut to the seam, do not cut the seam. THIS IS CRUCIAL, it allows the rear cable to bisect the top. It allows for the Top bead to lay flat to the car when open instead of humping the cable. I suppose you could pierce the top with a hole, but the slit works fine.

Starting from about 3 inches past the corners you will need to trim all the excess material off the entire back of the top

You have to go past the corner by 3 inches 4 is good too ok 3 to 4 inches.

DO NOT CUT THE STITCHES AND FOLD THE MATERIAL BACK SO YOU DON’T CUT THE OTHER SIDE OF THE TOP.

From this

To this

Raise the frame half way and safety it.

Grab the side cables out of your bag and insert the chain over the front stud.

Tie the other end to the pull string, and pull from the rear of the string, if there isn’t a pull string as in the case of my Cabrio World Top, but my AAAbest one had it. Then you will have to do a fish line to pull the cable end back through.

Take the free end and feed it through the side frame, then attach that loop to the spring, cover with the vinyl tube now pull on the bottom of the spring and hook onto the finger then bend the finger down.

Pick up your rear cable and measure it find the total length subtract the sheath, and divide in half and that is what you should have on both sides of the sheath, you can use a little electrical tape to make sure that the cable don’t slip and get off center it is terrible to find out that you have installed it and that your cable wont reach the holder on one side…

(don’t ask how I know this).

You can install the ends of the cable in the tray and tighten the nut about 3 spins too. Be sure to take the boot tabs out of your pocket and place them through the cable prior to tightening the nuts if you got one side nutted, then install them on the other and slide the one tab over.

Take your grease and lubricate the inside of the rear cable tray all the way around, a little goes a long way.

Take your grease and from the rear bead lay it on the top about a ¼ inch from the bead to the bead.

Line up your center marks fold the rear cable into the top and pinch it and insert it into the cable tray it pops right in with no strain or pain. Easy isn’t it.

Work for the center to the outer sides. Place the boot tabs seam inside into the marks and then pulling on the bead with the palm of your hand run it around the corner pulling it as you go and the boot tab you will find will pop in to place, you may have to pinch the bead in to the tray a bit but if you work it, pulling the bead around the corner it will just li fold into place.

Sorry couldn’t take pics while I was doing it and I dropped the camera batteries and crap shot all over.

Where the cable goes from the outer top to the inside you have to fold up the material so that it passes the relief cut the cable will bisect the cut and the top will lay flat.

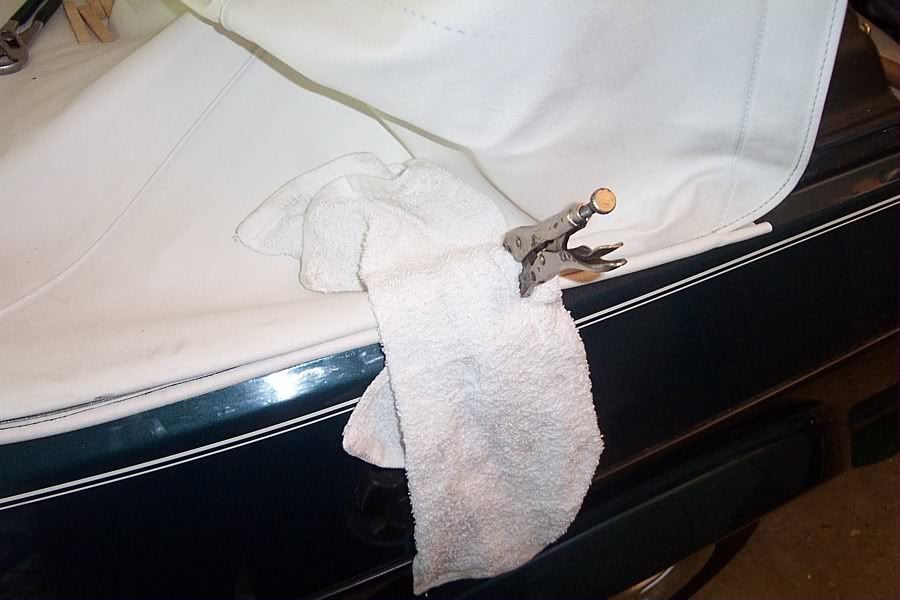

Here is where the spring clamps work well to hold the corners in tight. You can use small vice grips but you have to pad the jaws.

Place the hemostats on the cable bolt notch and clamp.

Pulling the hemostats to the front of the car tighten the nut as far as you can with your fingers. Move everything to the other side and repeat.

After all the basic tension is gone place the Hemostats on the notch and then using the 10mm offset tighten the nut about halfway to the measure that you took before loosening, Repeat on the other side.

As you are tightening it you may have to pinch the side together a bit. As it gets tighter, the lubing that you did you can pull the material to smooth it out as the cable tighter DO NOT OVER TIGHTEN YOU WILL SNAP THE CABLE.

When you are happy with the way it looks and the measurement is about the same you are done with the rear cable and it should only have taken you about 35-40 minutes.

Now replace the struts on the pivots strut on the inside and the washer on the outside.

Take the flap on the rear window frame and fold it over , and spray with hi-tack, then spray the rear window frame and allow to dry. Do both sides.

Now Pull the side flap on the frame get so that the finished edge of the top is next to the frame and that the roded edge is over the entire pig tail seal to the front and get it smooth and flat.

Find the holes for the nylon screw fasteners, and punch the hole out with a Phillips screwdriver then insert the nylon and tap into place with a hammer.

Take the seal tray and position it and screw it into place you did already install the foam when you were removing it if not put new foam on and cut to fit, make sure that the tray is at the outer most edge of the top this will insure that the seal will totally center to the glass.

Do the other side now.

Take your razor knife and run it along the inside frame to cut the excess material peal it off then spray carb cleaner on a rag and remove the excess glue.

Close the top and it should look like this

Open the top and latch it open

Work the vinyl in to the front edge so that the seam will curl a bit, when the curl is at 50 degrees move the vinyl and find a screw hole and then mark the top. Use a nail to pierce the top in all 8 holes the insert one screw through the bar at a time work from the middle to the ends alternately

Notch out for the locks

Close the top and see if the seam lies flat, it not then open and reposition it to get the seal to lay flat on the seal. You don’t have to remove all the screws to get the seam tight \ you may need to only loosen one or two screws pull the material one way or another

Take the flap out from under the edge, and spray Hi-Tack on the metal frame and the vinyl allow to dry.

Force the flap onto the metal and get the edge seated trim even with the latch.

Now the little top piece needs to be glued with silicone

Locate the holes for the nylon fasteners punch with a Phillips Screw driver you will need to trim out the front one as it is 2 layers thick, then insert the round nylon in the leading hole and the square one in the second hole.

Place the seal tray on the frame and make sure that it lays flat. Adjust as needed.

Locate the screw holes and insert the 4 screws not tight but loose

Screw the front screw into the hole a few turns

After all the screws are in a bit move the seal tray to the outer most edge that you can then tighten the screws down remove the leading screw (round.nylon).

After the seal tray is mounted you have to place a bit of silicone on the leading edge

Spray the tray with a bit of WD-40, spray the seals bottom lip.

To insert the seal place the front edge towards you into the tray then slightly pinch it and force it in to the back of the tray and it should pop in

Do about ¾ of it then slide it as far to the rear of the tray, this should allow the front to pop in and leading edge should be in the centered in to the front hole and screw it down with the bigger screw.

Wipe off the oozing silicone.

Now insert the lower seal in to the tray

Let’s turn our attention to the rear window.

Mark the inner part of the frame on the top.

Now make an X cut

DO NOT GO TO THE EXTREME CORNERS

Now Measure the bottom of the frame to the top bead, make sure that the frame is still square.

HINT: Most folks loose the ability to pull equally on the material to keep the

Frame Square and Parallel to the bead…your hands get tired, so you have to Measure the distance, and get BOTH sides of the bottom at the same height. Do this by stapling a few staples near the corners to set them at the same distance Measure and RE-Measure to get it right. Remove the staples and re-adjust you have to get this correct….

Second pull the material the same amount…shoot a staple then move over a few inches and shoot another… after the material is the same tension and the window is square, you can go back and pick up the remaining staples that you skipped.

Pulling the material tight shoot one or two staples into the corners then measure again, get it right, you can remove the staples and either pull it tighter or looser the difference should only be 1/8 of an inch. Once you are happy, start stapling from the outside edges back to the center.

To get the corner to lay flat you will need to make a relief cut or two.

I staple the sides next then go back to pick up the corners. You don’t have to pull the top part of the frame as tight…

Keep expanding the cut a tad to get the corner to lay flat

Where you are finished stapling make sure that the staples are firmly seated, and that if you run your finger along the tray it isn’t a snaggy motion, but a smooth one. If the staples aren’t seated smack them home with your anvil or punch they have to be well seated and smooth, if one or two bend over just smack them harder

When you are done you can trim off the excess even with the inner frame.

Lay a bead of silicone over the staples and into the lip of the frame. This will seal the holes for the staples, and provide a water barrier for the rubber after the window is installed.

Take your masons twine and wind it into the inner lip of the gasket on the window so that you have 2 wrappings.

Here is where you need a helper.

Insert the glass and gasket into the lower bit of the frame with the strings on the inside and press it firmly in all the way around, with the flat of your hands keep pressure on the glass, then have your helper slowly unwind the string, it will pull the gasket in to the inside of the car and seat it firmly on the inside lip. Wipe off any excess silicone that may ooze either on the inside or the outside.

The glass should be square.

Push the window assembly firmly in to the frame all the way around it may be a little high, but you will take care of that from the inside.

As you are pulling the strings pull at a angle while your helper is pushing in where you are pulling.

With the top latched and the front seal should seal flat to the top.

Now from the inside of the car

Place the defroster wires back into the holes in the gasket and then under the gasket and back out and connect to the defroster terminal then place the plastic cover back on.

With a Flashlight reach in to the trunk and pull the headliner onto the hooks and with a needle node bend to you the metal fingers then smack with the hammer.

Replace the two side cover pieces, you may have to trim the tube a bit I find that if I have ½ inch removed from the top the plastic cover will lay flat , insert the rear screw (longer of the two) it has the snap for the boot then replace the front screw (shorter screw). The snap goes to the back.

Replace the parcel shelf, raise the seat now clean your finger prints and marks off the top with Whestley’s Bleach White and a brush,,,,, Clean the rear window inside and out,

Pop a brew or two and you are done.

If you do a test drive and there is more noise than ever at speed you may need to adjust the J-hooks tighter.

Enjoy