well, finally got around to working on my cold start problem.

tested the WUR and it was 9 OHMs, bentley says no lower then 20.

i knew it had to be the WUR cuz i've replaced everything else.

so i tested the one on the parts car and it was 20 OHMs, took it off and put it on mine and it ran WORSE then before!

so, i have a WUR from a volvo 240T, it's for my turbo setup, i put it on and she fired right up and idled great!

after that i tackled the injector o-rings. first time doing this job, a lot easier then i thought it would be!

man the old o-rings were SHOT! hard as a rock and all cracked.

the thorttle response is so much better now with the new o-rings, maybe the WUR helped this too? i don't know, but it runs like a different car now.

next on the list is the water pump, found out thats where my loud bearing noise is coming from.

then timing belt/ tensioner and a new cam seal...leaking bad.

cold start

Moderators: kamzcab86, CalAltaDubber

-

1lowcab

- DropTop Pimp

- Posts: 1809

- Joined: Fri Apr 25, 2003 12:42 am

- Do you own a Cabriolet?: Yes

- Location: mt. vernon, ohio

cold start

If you can't beat them, drop the top and pimp by 'em!

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

Re: cold start

Do this too......1lowcab wrote:....but it runs like a different car now.....

http://dana.ucc.nau.edu/~kaw5/CISidle.htm

Plan on the right motor mount while you are in there, access will never be easier. Get a coolant pump housing for the coolant pump, either separate or as an assembly. Also change the auxilliary shaft seals and the crank pulley seal. Once it's all buttoned up, you'll be good in there for several years.1lowcab wrote:.......next on the list is the water pump, found out thats where my loud bearing noise is coming from.

then timing belt/ tensioner and a new cam seal...leaking bad.

-

1lowcab

- DropTop Pimp

- Posts: 1809

- Joined: Fri Apr 25, 2003 12:42 am

- Do you own a Cabriolet?: Yes

- Location: mt. vernon, ohio

thats a great write up!! thanks for the link.

how hard are the auxilliary shaft seals and the crank pulley seal to do? any special tools needed?

good idea about the motor mount, i need to do them all actually.

been waiting till i get some other stuff outta the way then i'm going poly mounts.

how hard are the auxilliary shaft seals and the crank pulley seal to do? any special tools needed?

good idea about the motor mount, i need to do them all actually.

been waiting till i get some other stuff outta the way then i'm going poly mounts.

If you can't beat them, drop the top and pimp by 'em!

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

- Briano1234

- Whats that smell?

- Posts: 4105

- Joined: Mon Mar 21, 2005 5:45 am

- What year is your cabby?: 1992

- Do you own a Cabriolet?: No

- Location: Duluth, Ga

- Contact:

if you are off-roading, poly mounts are a good thing, but for street driving they are very prone to vibrations...and not the good feeling ones.1lowcab wrote:thats a great write up!! thanks for the link.

how hard are the auxilliary shaft seals and the crank pulley seal to do? any special tools needed?

good idea about the motor mount, i need to do them all actually.

been waiting till i get some other stuff outta the way then i'm going poly mounts.

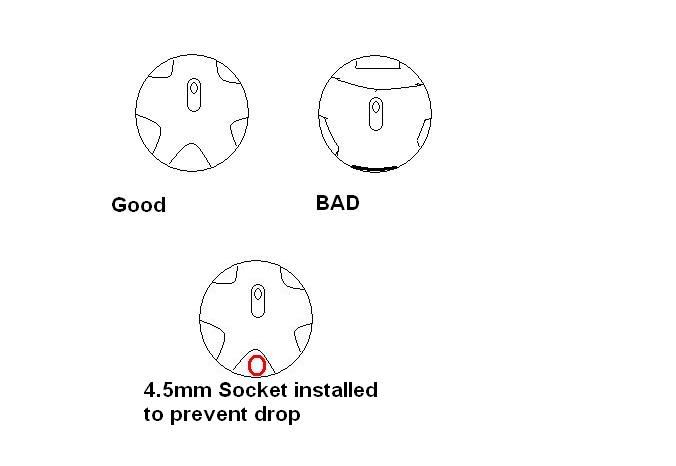

I would suggest HD Diesel mounts from a dealer, and then add my 4mm socket to the bottom to ensure long life.

Briano

Yes as matter of fact, I have the Luck o'the Irish...everything I touch turns to fertilizer of the bovine variety.

You can lead a user to a link, but you can't make him Click....

Yes as matter of fact, I have the Luck o'the Irish...everything I touch turns to fertilizer of the bovine variety.

You can lead a user to a link, but you can't make him Click....

-

1lowcab

- DropTop Pimp

- Posts: 1809

- Joined: Fri Apr 25, 2003 12:42 am

- Do you own a Cabriolet?: Yes

- Location: mt. vernon, ohio

cool, thanks for the info briano. never would of thought of sticking a socket in there!

can you mix and match motor mounts? like maybe use poly for the front and HD diesel for the rest?

can you mix and match motor mounts? like maybe use poly for the front and HD diesel for the rest?

If you can't beat them, drop the top and pimp by 'em!

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

85 Mercedes 500SEL grey market euro

Bunch of GM crap

In need of a VW lol

- Briano1234

- Whats that smell?

- Posts: 4105

- Joined: Mon Mar 21, 2005 5:45 am

- What year is your cabby?: 1992

- Do you own a Cabriolet?: No

- Location: Duluth, Ga

- Contact:

Fit the socket that has to be pushed a bit in to the mount, that way the strain will be offset at the bottom. The addition of the socket will insure that the mount is longer lasting as there is support at the bottom.

I personally have only heard of all poly or all hd mounts. I have heard of nothing but terrible vibrations on a Dailydriver that they installed poly mounts on.

I personally have only heard of all poly or all hd mounts. I have heard of nothing but terrible vibrations on a Dailydriver that they installed poly mounts on.

Briano

Yes as matter of fact, I have the Luck o'the Irish...everything I touch turns to fertilizer of the bovine variety.

You can lead a user to a link, but you can't make him Click....

Yes as matter of fact, I have the Luck o'the Irish...everything I touch turns to fertilizer of the bovine variety.

You can lead a user to a link, but you can't make him Click....

Cam, crank and auxilliary shaft seals are identical with a similar degree of difficulty which is not very hard. Hardest part of the three identical seals is getting the gear/sprocket bolts loose, then re-tightened.1lowcab wrote:.......how hard are the auxilliary shaft seals and the crank pulley seal to do? any special tools needed?.......

The "other" seal is an o-ring behind the auxilliary shaft seal/thrust bearing housing. The housing is retained with two bolts, remove them and it slides right out. Your replacement o-ring should be green, it's probably Viton. (I have no clue what "Viton" really is other than a buzz word).

Probably best to loosen cam and crank gear bolts before the timing belt is removed. A prybar through one of the cam sprocket holes and a socket on a breaker bar will usuallly get that done.

Move the breaker bar to the crank pulley sprocket bolt, braced to the ground. Stand clear and quicky, briefly bump the starter, bolt is loose. Sounds a bit sketchy, but it works very well, lots of Pros do it all the time.

Pass a 13mm deep well socket attached to a ratchet for a handle through one of the auxilliary shaft sprocket holes, seat it on one of the auxilliary shaft seal/thrust bearing housing bolt heads to keep the sprocket from turning, apply your breaker bar to the bolt.

Don't lose any of the woodruff keys.

Put the engine on #1 TDC before you remove the belt and the job will go much easier.

Oil each seal prior to installation, they usually press in fairly easily, sometimes just finger pressure.

I slice a section from a smooth sided water or soda bottle to wrap around the end of each shaft to both guide and protect the seal during instalation.